| Availability: | |

|---|---|

| Quantity: | |

MR09

MR

09

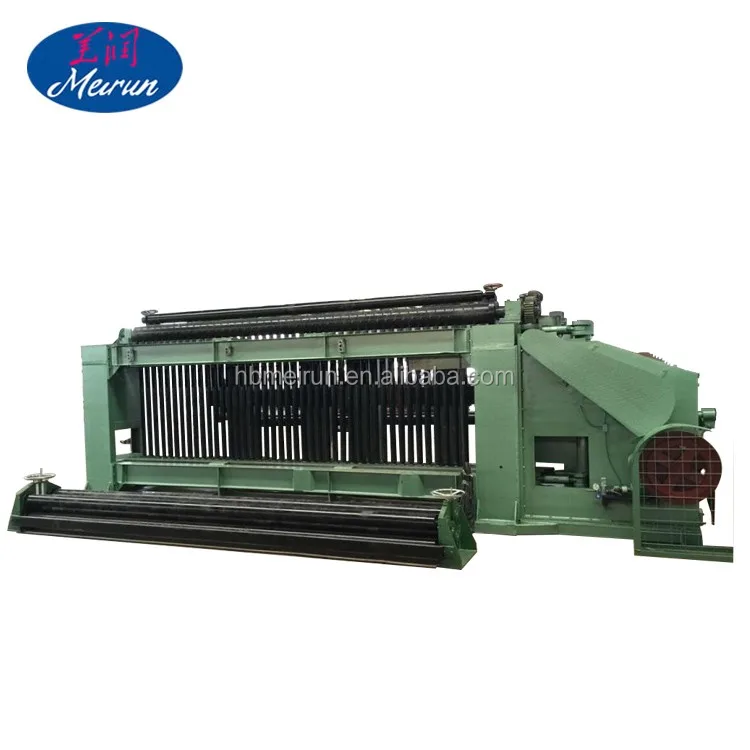

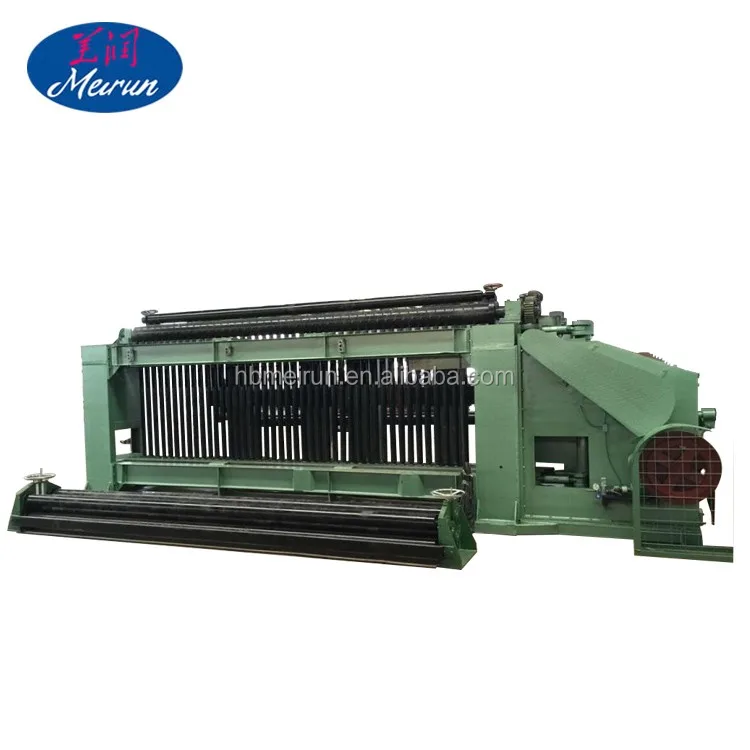

1.Stone cage net machine is also called the hexagonal wire netting machine, guest net machine, hexagonal wire netting machine is the professional equipment production is hexagonal wire netting, raw material can be galvanized iron wire or PVC wire,

2.Stone cage net machine is the firstchoice of weaving large size, wide and thick wire hexagonal wire mesh.And it has characteristics of stable performance,low noice and high effiency.

| Product specification | 60*80mm | 80*100mm | 80*120mm 100*120mm | 120*150mm |

| Wire diameter | 2-4mm | 2-4mm | 2-4mm | 2-4mm |

| Side wire diameter | 2.5-3mm | 2.5-3mm | 2.5-3mm | 2.5-3mm |

| Tied wire diameter | 2.2mm | 2.2mm | 2.2mm | 2.2mm |

| Max width | 4000mm | 4000mm | 4000mm | 4000mm |

| Weaving speed | 50-60times/hour | 50-60times/hour | 50-60times/hour | 50-60times/hour |

| Power | 22KW | 22KW | 22KW | 30KW |

| Voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Weight | 15T | 15.5T | 16T | 16T |

| Dimension | 7.2*1.4*2.3m | 7.2*1.4*2.3m | 7.2*1.4*2.3m | 7.2*1.4*2.3m |

MF Wire Tension Machine

| Upper roller | 4600*Φ133mm,2pcs |

| Under roller | 4600*Φ133mm,3pcs |

| Weight | 650kg |

| Overall size | 5000*680*710mm |

| Spring rod quantity | 6pieces |

| Spring rod rotate speed | 385m/h |

| Maximum length of spring | 2000mm |

| Spring rod diameter | 25mm |

| Spring layer quantity | ≥6 |

| Maximum zinc-plated wire diameters | 4mm |

| Maximum wire diameter after being covered by plastic | 5mm |

| Motor power | 2.2kw,5kw |

| Weight | 480kg |

| Dimension | 1960*600*1450mm |

Netting Winding Machine

| Front seat | 1000*750*1100mm |

| Back seat | 1000*800*700mm |

| Net roller | Φ180*4800mm |

| Motor power | 1.5kw |

| Weight | 850kg |

Stone cage net can be used in the slope support, foundation pit supporting, mountain rockface net-suspended spray, slope vegetative guarding block (green), railway highway isolation, it can also make luggage, gauze pad, used in rivers, DAMS and scour prevention of seawall protection, reservoir, river closure.

1.The spare parts and control cabinet will be loaded in wooden box.

2.The main machine is nude packing or plastic packing.

3.Also can do as customer's request.

Our company:

Our company is a professional screen machinery manufacturing company with many years of experience in China. Our company focuses on the manufacturing and trading of various screen products and related machines.We have our own factory and professional r&d team to ensure the quality and strict testing of the products.For some machines, our market share is as high as 70%.All of our machines are in line with international quality standards and customers' needs and have been greatly appreciated in various markets around the world.So we are your wise choice and best friend.

Our service:

1.If the buyer need,we can send our technical staff to the buyers factory to install the machine and providing the training in 30 days after the machines arrived the destination pory

2.Maintenance period:One year for whole machine except vulnerable parts

3.The number of technical persons :one technician per machine

4.The fees:the buyer have to pay the technical salary 100 USD per day,and the round-trip tiket,accommodation and other related fees

5.During the maintenance period.if the parts are broken caused by the product problem.seller will offer the parts for free,if you need we assign the tachicians to your factory ,then you will pay some related fees.

1.Stone cage net machine is also called the hexagonal wire netting machine, guest net machine, hexagonal wire netting machine is the professional equipment production is hexagonal wire netting, raw material can be galvanized iron wire or PVC wire,

2.Stone cage net machine is the firstchoice of weaving large size, wide and thick wire hexagonal wire mesh.And it has characteristics of stable performance,low noice and high effiency.

| Product specification | 60*80mm | 80*100mm | 80*120mm 100*120mm | 120*150mm |

| Wire diameter | 2-4mm | 2-4mm | 2-4mm | 2-4mm |

| Side wire diameter | 2.5-3mm | 2.5-3mm | 2.5-3mm | 2.5-3mm |

| Tied wire diameter | 2.2mm | 2.2mm | 2.2mm | 2.2mm |

| Max width | 4000mm | 4000mm | 4000mm | 4000mm |

| Weaving speed | 50-60times/hour | 50-60times/hour | 50-60times/hour | 50-60times/hour |

| Power | 22KW | 22KW | 22KW | 30KW |

| Voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Weight | 15T | 15.5T | 16T | 16T |

| Dimension | 7.2*1.4*2.3m | 7.2*1.4*2.3m | 7.2*1.4*2.3m | 7.2*1.4*2.3m |

MF Wire Tension Machine

| Upper roller | 4600*Φ133mm,2pcs |

| Under roller | 4600*Φ133mm,3pcs |

| Weight | 650kg |

| Overall size | 5000*680*710mm |

| Spring rod quantity | 6pieces |

| Spring rod rotate speed | 385m/h |

| Maximum length of spring | 2000mm |

| Spring rod diameter | 25mm |

| Spring layer quantity | ≥6 |

| Maximum zinc-plated wire diameters | 4mm |

| Maximum wire diameter after being covered by plastic | 5mm |

| Motor power | 2.2kw,5kw |

| Weight | 480kg |

| Dimension | 1960*600*1450mm |

Netting Winding Machine

| Front seat | 1000*750*1100mm |

| Back seat | 1000*800*700mm |

| Net roller | Φ180*4800mm |

| Motor power | 1.5kw |

| Weight | 850kg |

Stone cage net can be used in the slope support, foundation pit supporting, mountain rockface net-suspended spray, slope vegetative guarding block (green), railway highway isolation, it can also make luggage, gauze pad, used in rivers, DAMS and scour prevention of seawall protection, reservoir, river closure.

1.The spare parts and control cabinet will be loaded in wooden box.

2.The main machine is nude packing or plastic packing.

3.Also can do as customer's request.

Our company:

Our company is a professional screen machinery manufacturing company with many years of experience in China. Our company focuses on the manufacturing and trading of various screen products and related machines.We have our own factory and professional r&d team to ensure the quality and strict testing of the products.For some machines, our market share is as high as 70%.All of our machines are in line with international quality standards and customers' needs and have been greatly appreciated in various markets around the world.So we are your wise choice and best friend.

Our service:

1.If the buyer need,we can send our technical staff to the buyers factory to install the machine and providing the training in 30 days after the machines arrived the destination pory

2.Maintenance period:One year for whole machine except vulnerable parts

3.The number of technical persons :one technician per machine

4.The fees:the buyer have to pay the technical salary 100 USD per day,and the round-trip tiket,accommodation and other related fees

5.During the maintenance period.if the parts are broken caused by the product problem.seller will offer the parts for free,if you need we assign the tachicians to your factory ,then you will pay some related fees.