| Availability: | |

|---|---|

| Quantity: | |

MRCH-1

Meirun

MRCH-1

1.Perforated metal mesh machine includes punching machine, auto-feeder platform, CNC control electric cabinet. The machine is with high quality and most parts are from chinese famous brand and some are from Taiwan.

2.Suitable material to the perforated metal mesh machine: 304 stainless steel sheet low carbon steel sheet,galvanized sheet, PVC sheet, cold-rolled sheet,hot-rolled sheet, aluminum sheet, copper sheet .

3.The machine is welded by steel plate. Equipped with system of double-roller automatic feeding, compulsory and automatic lubricating, low pressure protection for stopping and pneumatic clutch, this machine can meet various requirements from customers.

4.The machine can be used for producing round hole sheet, wind and dust suppression mesh, square hole mesh, decoration sheet, polygon mesh and other strange shape of mesh.

5.The machine is automatic and pneumatic and it is very during and stable.

6.It is easy to use, usually 2 men are enough to operate 4 or 6 sets of this type of machine. 6.According to the sheet the customer produce, some other small equipment is need, such as coiler, decoiler and leveling machine. Customers can choose to buy it or make it by themselves.

7.one is weleded by steel plate with different specifications of mold plus the rack type feeder or roller type feeder.

Product main technical specification:

| Specification | JH21-100 | JH21-125 | JH21-160 | JH21-200 | |

| Nominal pressure(KN) | 1000 | 1250 | 1600 | 2000 | |

| Nominal force stroke(mm) | 5 | 5 | 6 | 6 | |

| Slider stroke(mm) | 150 | 160 | 180 | 200 | |

| Number of slider stroke(s.p.m) | 50 | 50 | 45 | 40 | |

| Max. die set height(mm) | 320 | 370 | 400 | 450 | |

| Die set height adjustment(mm) | 80 | 100 | 110 | 110 | |

| Distance from slider center to frame(mm) | 300 | 360 | 390 | 430 | |

| Worktable dimension(L x W) (mm) | 580X1000 | 700X1100 | 760X1200 | 840X1400 | |

| Workbench plate hole size(mm) | 180 | 160 | 180 | 200 | |

| Thickness of the worktable panel(mm) | 120 | 120 | 150 | 180 | |

| Slider ground size (L x W) (mm) | 420X560 | 520X620 | 580X700 | 650X880 | |

| Size of the handle hole(mm) | 60X80 | 70X80 | 70X100 | 70X100 | |

| Vertical columns distance(mm) | 640 | 640 | 660 | 820 | |

| Overall dimension(L x W x H) (mm) | 1820X1350X2800 | 1900X1300X3300 | 2040X1360X3300 | 2370X1600X3900 | |

| Motor | Model | Y132M-4 | Y160L-6 | Y180L-6 | Y200L-6 |

| Power(kw) | 7.5 | 11 | 15 | 18.5 | |

| Total Weight(kg) | 8500 | 9800 | 13200 | 19500 | |

Features:

1. Its structure is simple, operation convenience, function credibility, the usage maintain convenience.

2. J23 series shut type list orders the pressure machine fuselage of airplane srtaight line form design, well balanced to be subjected to dint, constant form, rigid and strong.

3. Extemely high closing height, pack the mould space big, slippery piece the piece six noodles direction, the accurancy is high, stability good.

4. Outside support type especially the big machine do, exaltation the tool machine install stability, safety, inside place type, oil road, electric circuit, beauty clean and net, have a safety, dependable type more,

5. The hand operation button the switch match pressure machine national security standard.

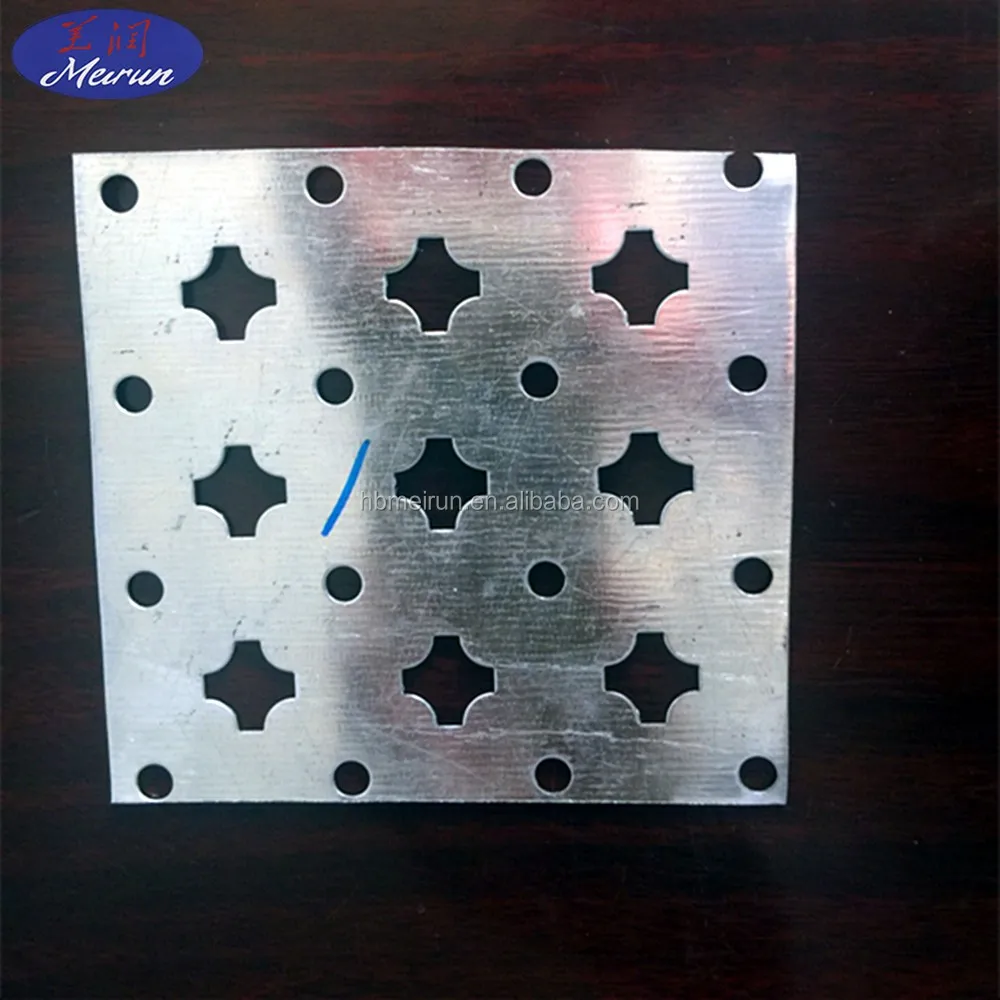

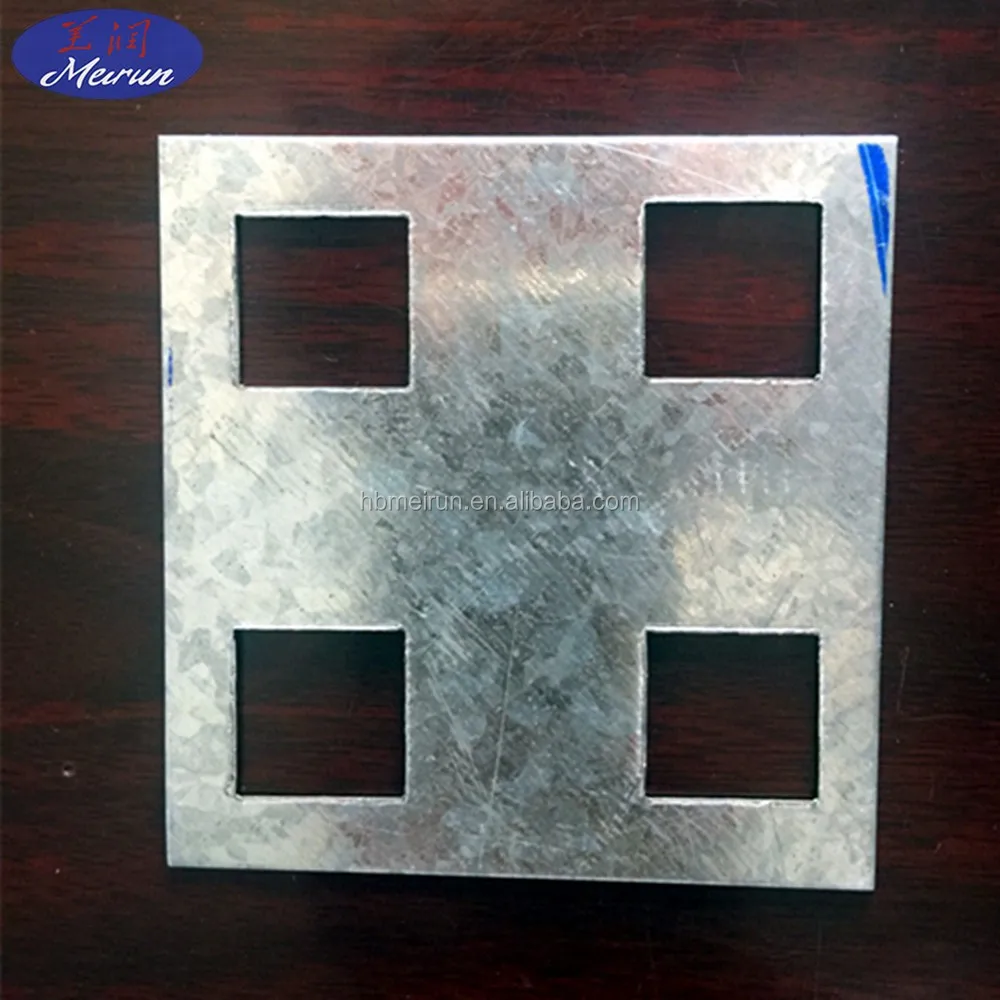

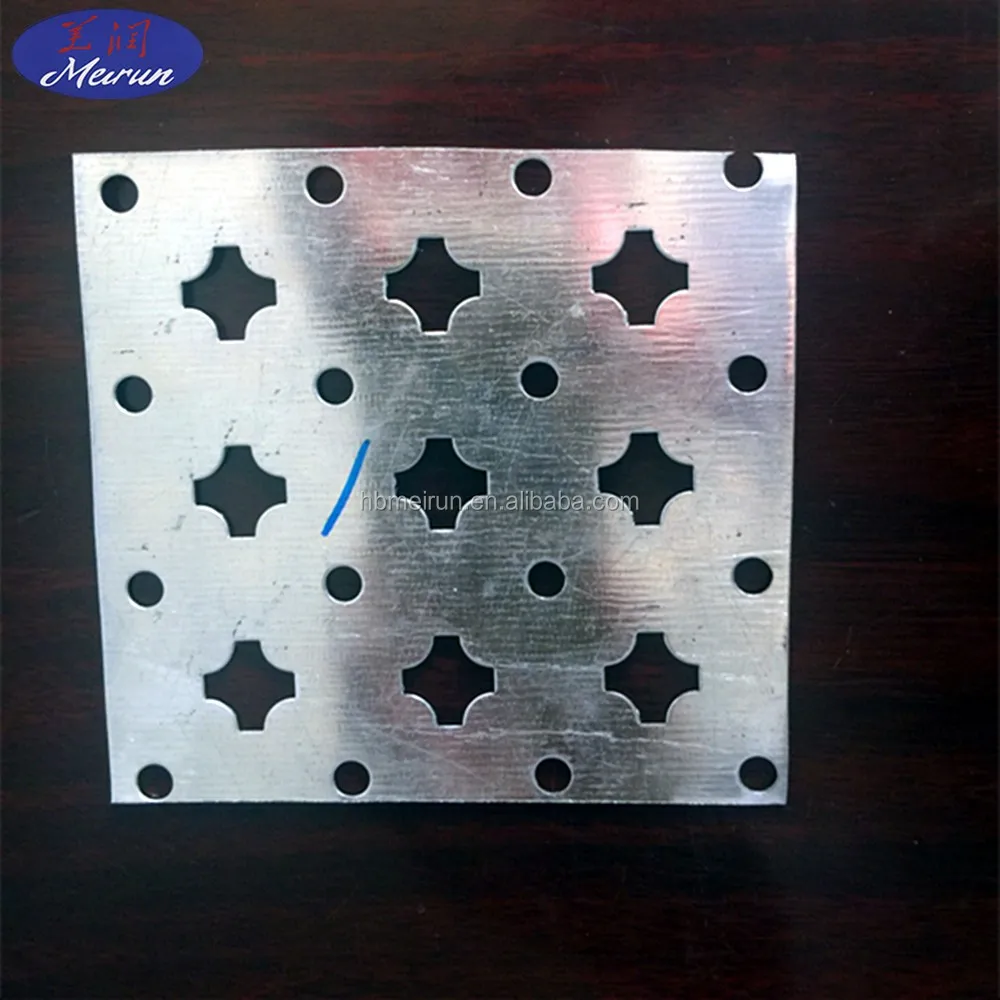

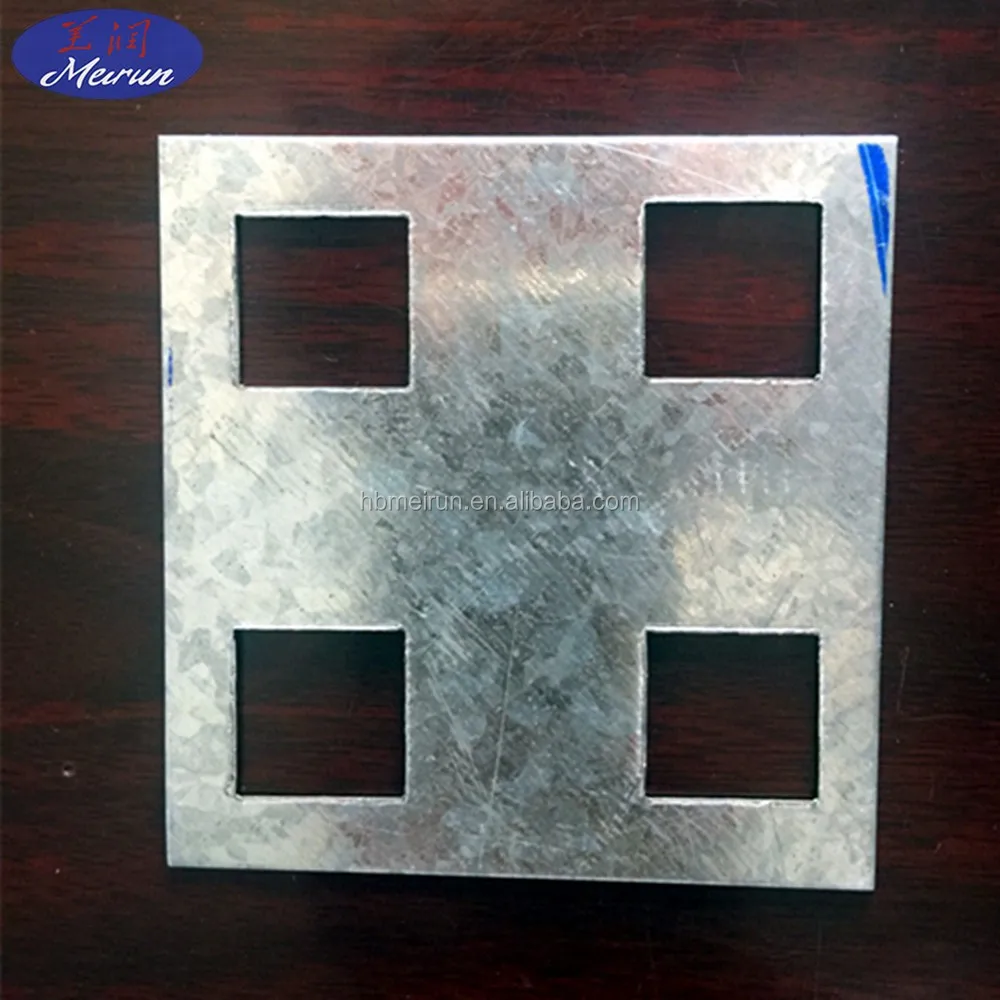

Hole shapes: square hole, round hole, cross hole, long round hole, diamond hole, triangl hole, scale hole, pentagram hole, fish scale hole and so on.

The the sheet metal perforating machine dies are made by our technical personnel. As long as you give us draws we will make any holes for you.

Guarantee: one year, during this year, any broken parts caused by the quality, we can offer free,after this year can offer with the lowest cost.

Install and training: we will send one engineer to install and training the machine for the customer, and need you pay the engineer the salary usd100/day, and the tickets and hotel and food ,if the machine price including the install salary the customer just pay for the tickets, hotel and

foods.

Delivery time: 20days after advance payment some times we have stock ,then can load container when we get the advance

Payment terms: T/T, 30% in advance, and the balance before delivery.

About Us:

Hebei Meirun Wire Mash CO, LTD is located in the Anping county, Hengshui, Hebei. Anping county is the hometown of the wire mash having hundreds of years history and in the international screen production it occupies an important position. And our company produce, research and develop kinds of wire mesh making machine and we have our own factory. About some of machines our market share is about 70%.

Welcome to visit our company!

THE TENET OF THE FACTORY:

The tenet of our company are integrity as a foundation, customer first, upgrading quality of products, focusing on equality and mutual benefit and promoting common development.

Q: Why I choose your company?

A:1)Our company produce, research and develop kinds of wire mesh making machine.

2)Our company has about 20 years with strong experience and advanced technique.

3)Best Quality & Best Service with competitive price. 1 year guarantee and lifetime maintenance.

4)We have CE certificate and ISO 9001.

5)We have Professional technical team, and will supply 24 hours service.

Q:What about the quality of your products?

A:High quality products, Real factory trustworthy.

Q:Where is your factory located? How can I visit there?

A:Our factory is Noth Of Weimin East Street, Anping county, Hengshui, Hebei, China(Mainland). When you conform the flight NO. and time, please tell me then we will pick you up at Airport.

Q:What are your terms of payment?

A:Payment terms usually T/T as you like.

1.Perforated metal mesh machine includes punching machine, auto-feeder platform, CNC control electric cabinet. The machine is with high quality and most parts are from chinese famous brand and some are from Taiwan.

2.Suitable material to the perforated metal mesh machine: 304 stainless steel sheet low carbon steel sheet,galvanized sheet, PVC sheet, cold-rolled sheet,hot-rolled sheet, aluminum sheet, copper sheet .

3.The machine is welded by steel plate. Equipped with system of double-roller automatic feeding, compulsory and automatic lubricating, low pressure protection for stopping and pneumatic clutch, this machine can meet various requirements from customers.

4.The machine can be used for producing round hole sheet, wind and dust suppression mesh, square hole mesh, decoration sheet, polygon mesh and other strange shape of mesh.

5.The machine is automatic and pneumatic and it is very during and stable.

6.It is easy to use, usually 2 men are enough to operate 4 or 6 sets of this type of machine. 6.According to the sheet the customer produce, some other small equipment is need, such as coiler, decoiler and leveling machine. Customers can choose to buy it or make it by themselves.

7.one is weleded by steel plate with different specifications of mold plus the rack type feeder or roller type feeder.

Product main technical specification:

| Specification | JH21-100 | JH21-125 | JH21-160 | JH21-200 | |

| Nominal pressure(KN) | 1000 | 1250 | 1600 | 2000 | |

| Nominal force stroke(mm) | 5 | 5 | 6 | 6 | |

| Slider stroke(mm) | 150 | 160 | 180 | 200 | |

| Number of slider stroke(s.p.m) | 50 | 50 | 45 | 40 | |

| Max. die set height(mm) | 320 | 370 | 400 | 450 | |

| Die set height adjustment(mm) | 80 | 100 | 110 | 110 | |

| Distance from slider center to frame(mm) | 300 | 360 | 390 | 430 | |

| Worktable dimension(L x W) (mm) | 580X1000 | 700X1100 | 760X1200 | 840X1400 | |

| Workbench plate hole size(mm) | 180 | 160 | 180 | 200 | |

| Thickness of the worktable panel(mm) | 120 | 120 | 150 | 180 | |

| Slider ground size (L x W) (mm) | 420X560 | 520X620 | 580X700 | 650X880 | |

| Size of the handle hole(mm) | 60X80 | 70X80 | 70X100 | 70X100 | |

| Vertical columns distance(mm) | 640 | 640 | 660 | 820 | |

| Overall dimension(L x W x H) (mm) | 1820X1350X2800 | 1900X1300X3300 | 2040X1360X3300 | 2370X1600X3900 | |

| Motor | Model | Y132M-4 | Y160L-6 | Y180L-6 | Y200L-6 |

| Power(kw) | 7.5 | 11 | 15 | 18.5 | |

| Total Weight(kg) | 8500 | 9800 | 13200 | 19500 | |

Features:

1. Its structure is simple, operation convenience, function credibility, the usage maintain convenience.

2. J23 series shut type list orders the pressure machine fuselage of airplane srtaight line form design, well balanced to be subjected to dint, constant form, rigid and strong.

3. Extemely high closing height, pack the mould space big, slippery piece the piece six noodles direction, the accurancy is high, stability good.

4. Outside support type especially the big machine do, exaltation the tool machine install stability, safety, inside place type, oil road, electric circuit, beauty clean and net, have a safety, dependable type more,

5. The hand operation button the switch match pressure machine national security standard.

Hole shapes: square hole, round hole, cross hole, long round hole, diamond hole, triangl hole, scale hole, pentagram hole, fish scale hole and so on.

The the sheet metal perforating machine dies are made by our technical personnel. As long as you give us draws we will make any holes for you.

Guarantee: one year, during this year, any broken parts caused by the quality, we can offer free,after this year can offer with the lowest cost.

Install and training: we will send one engineer to install and training the machine for the customer, and need you pay the engineer the salary usd100/day, and the tickets and hotel and food ,if the machine price including the install salary the customer just pay for the tickets, hotel and

foods.

Delivery time: 20days after advance payment some times we have stock ,then can load container when we get the advance

Payment terms: T/T, 30% in advance, and the balance before delivery.

About Us:

Hebei Meirun Wire Mash CO, LTD is located in the Anping county, Hengshui, Hebei. Anping county is the hometown of the wire mash having hundreds of years history and in the international screen production it occupies an important position. And our company produce, research and develop kinds of wire mesh making machine and we have our own factory. About some of machines our market share is about 70%.

Welcome to visit our company!

THE TENET OF THE FACTORY:

The tenet of our company are integrity as a foundation, customer first, upgrading quality of products, focusing on equality and mutual benefit and promoting common development.

Q: Why I choose your company?

A:1)Our company produce, research and develop kinds of wire mesh making machine.

2)Our company has about 20 years with strong experience and advanced technique.

3)Best Quality & Best Service with competitive price. 1 year guarantee and lifetime maintenance.

4)We have CE certificate and ISO 9001.

5)We have Professional technical team, and will supply 24 hours service.

Q:What about the quality of your products?

A:High quality products, Real factory trustworthy.

Q:Where is your factory located? How can I visit there?

A:Our factory is Noth Of Weimin East Street, Anping county, Hengshui, Hebei, China(Mainland). When you conform the flight NO. and time, please tell me then we will pick you up at Airport.

Q:What are your terms of payment?

A:Payment terms usually T/T as you like.