| Complete machine weight: | |

|---|---|

| Weight: | |

| Size : | |

| Availability: | |

| Quantity: | |

MRJWJ

Meirun

8463300000

Corner Bead Keel Angle Iron Roll Forming Machine with Punching

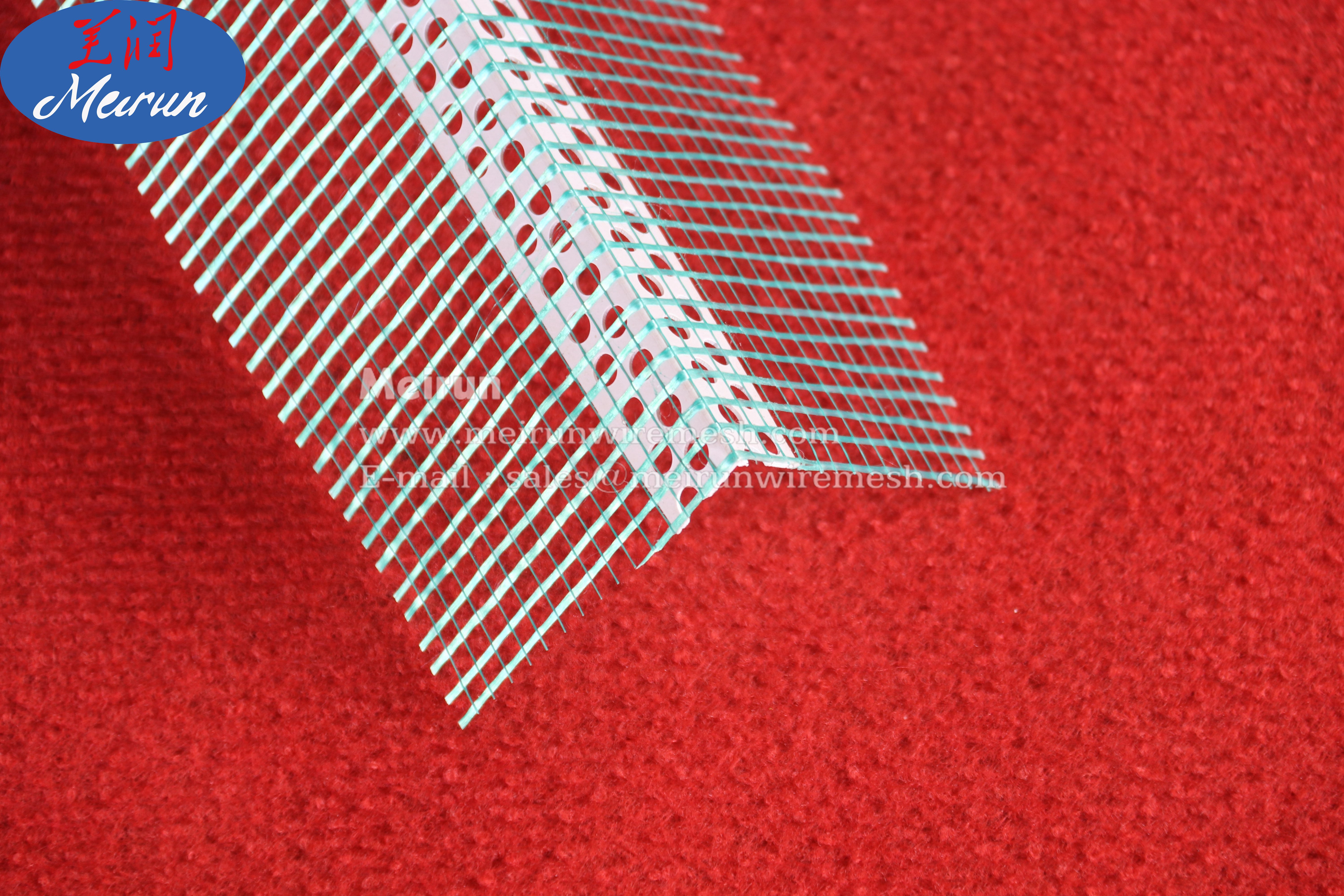

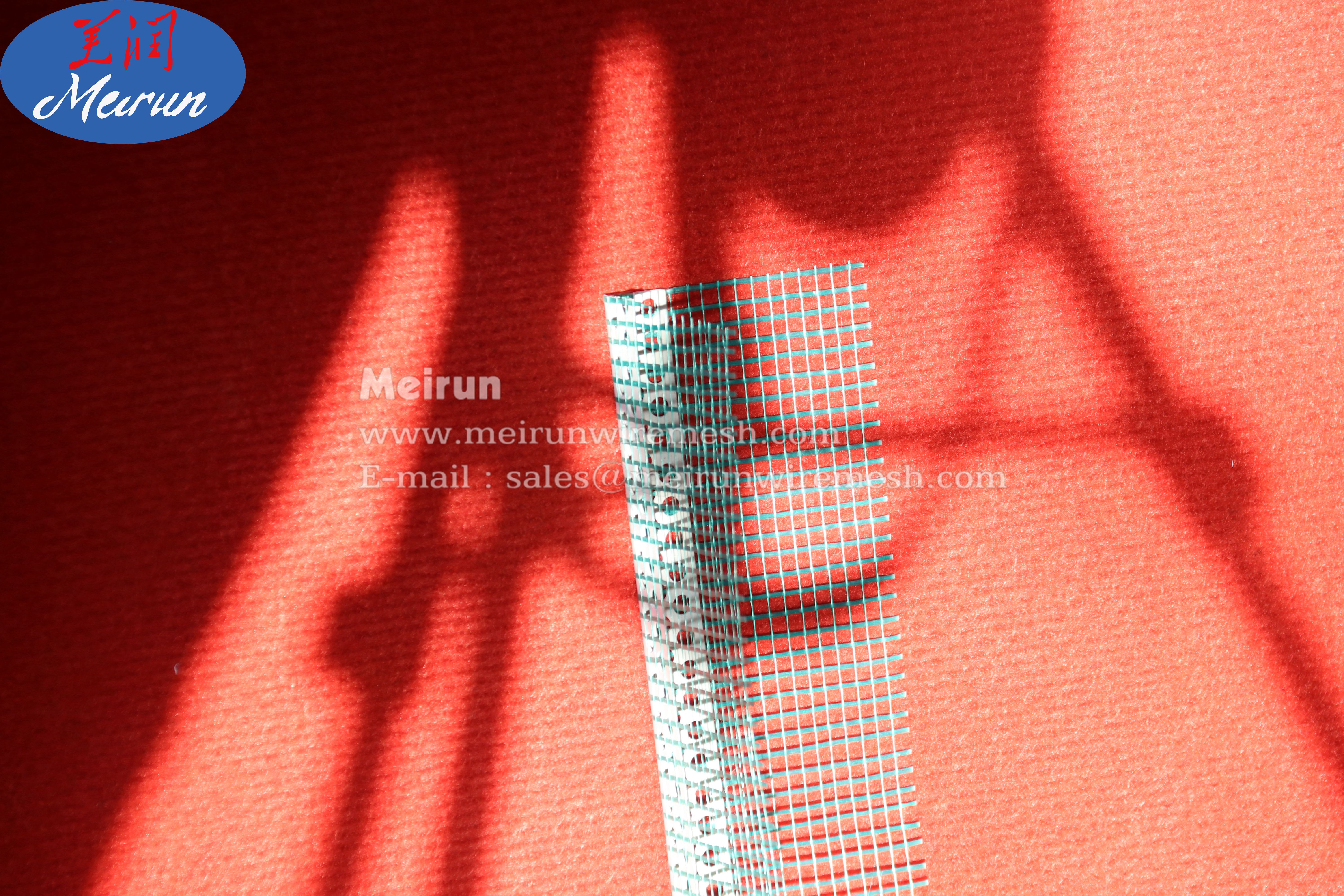

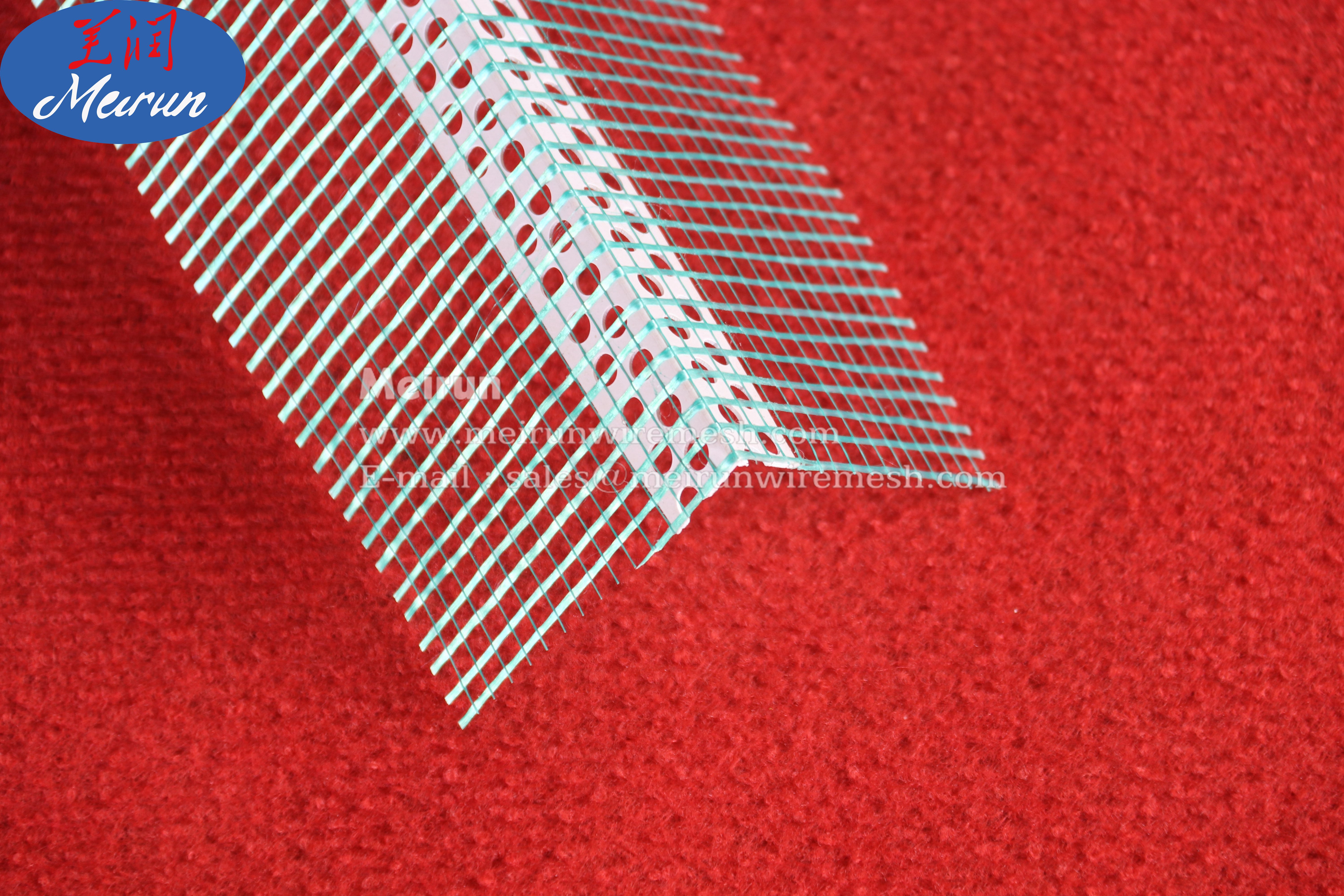

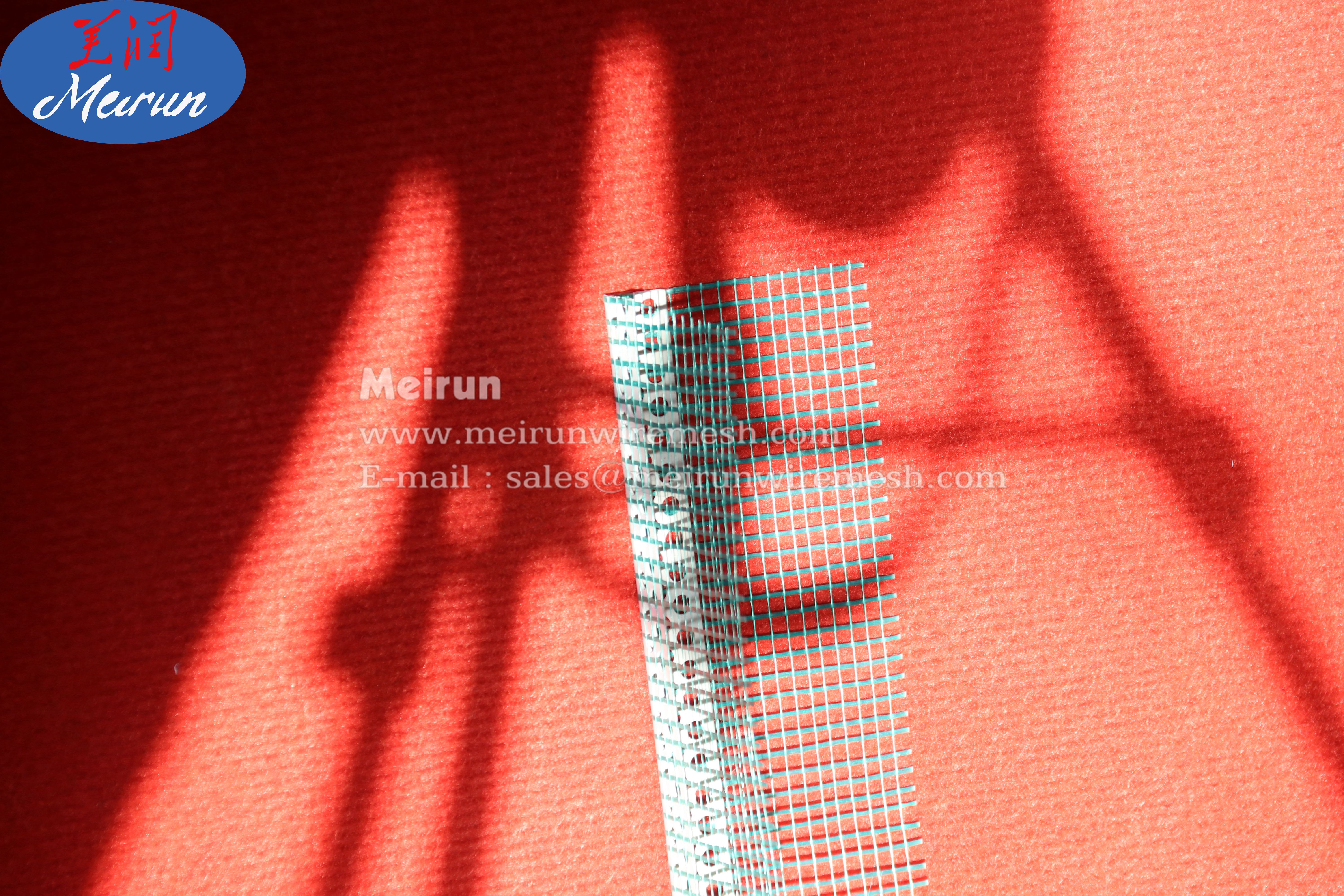

Angle bead production line is used to produce the angle bead which is mainly used to protect the angle of the wall.

The expanded metal bead machine can produce angle bead, corner bead, plaster stop, corner mesh, mini mesh, etc.

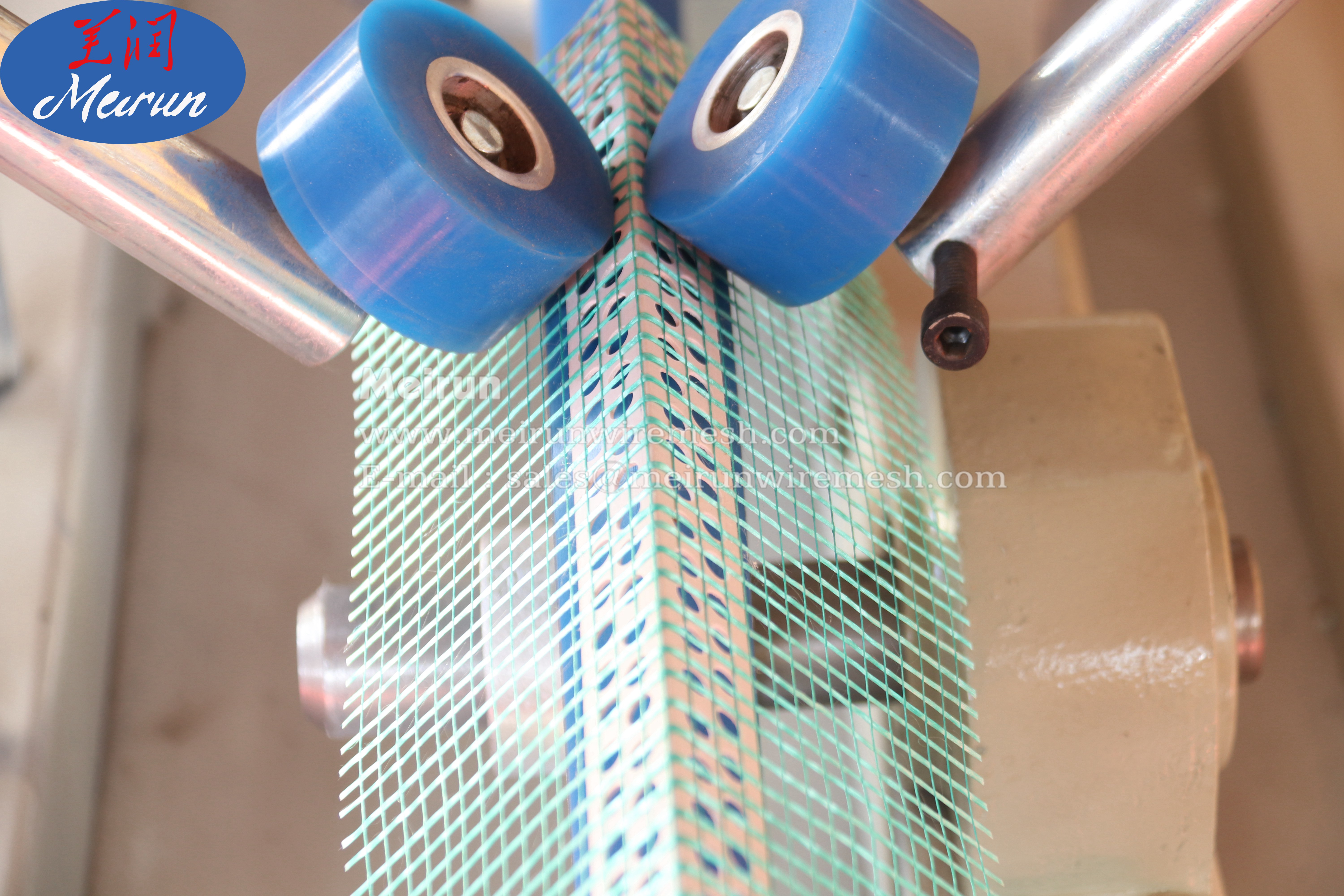

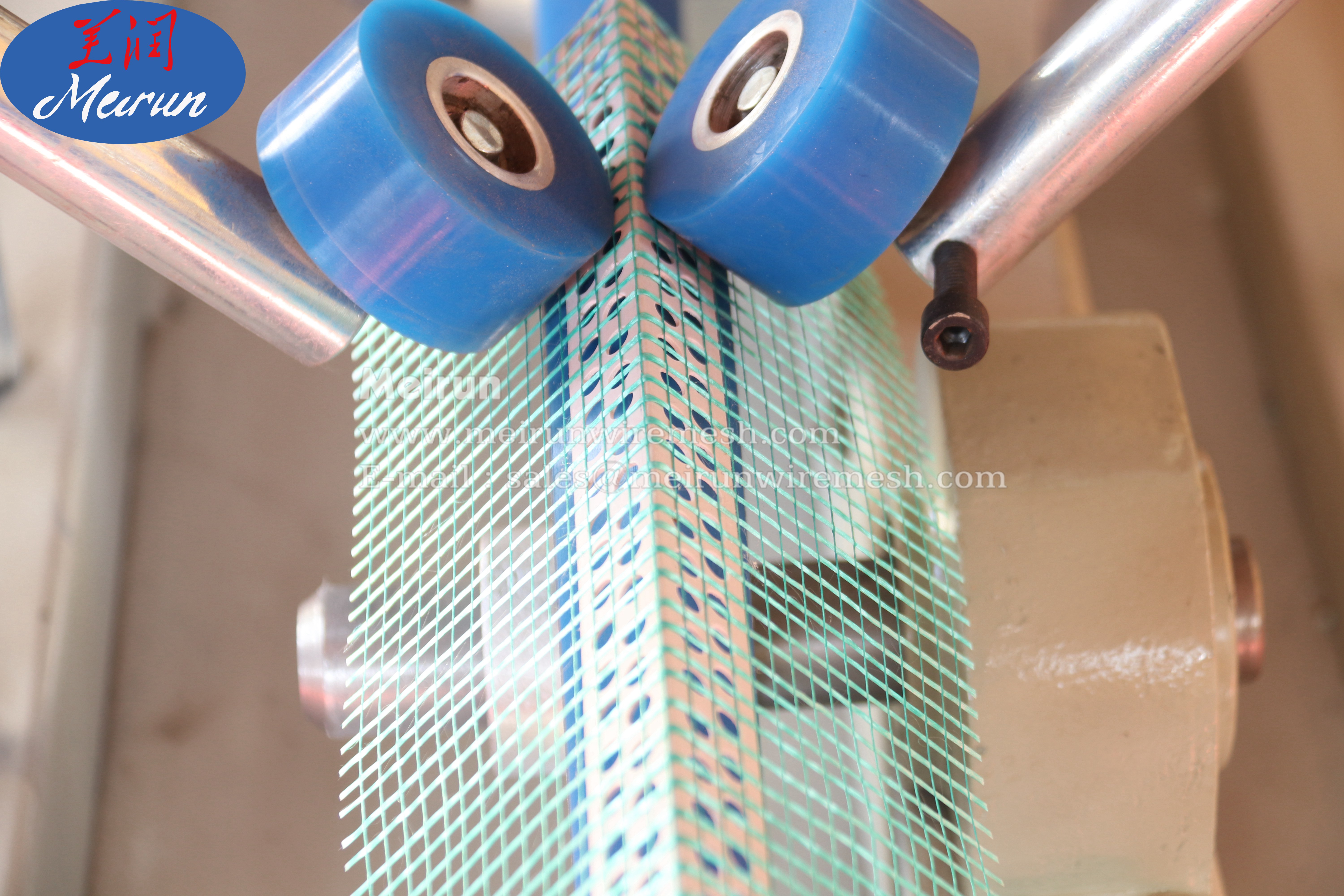

| 1.Formed Material | PPGI,GI,AI | Thickness:0.3-0.8mm | ||

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 18 rows(As your requirement) | ||

| Diameter of shaft | 40mm solid shaft | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | 350 H steel | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 4500*600*1600(customize) | |||

| Weight | 3.5T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 3KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 15-20m/min | The speed depends on the shape of the tile and the thickness of the material. | ||

Corner Bead Keel Angle Iron Roll Forming Machine with Punching

Angle bead production line is used to produce the angle bead which is mainly used to protect the angle of the wall.

The expanded metal bead machine can produce angle bead, corner bead, plaster stop, corner mesh, mini mesh, etc.

| 1.Formed Material | PPGI,GI,AI | Thickness:0.3-0.8mm | ||

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 18 rows(As your requirement) | ||

| Diameter of shaft | 40mm solid shaft | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | 350 H steel | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 4500*600*1600(customize) | |||

| Weight | 3.5T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 3KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 15-20m/min | The speed depends on the shape of the tile and the thickness of the material. | ||