| Machine name : | |

|---|---|

| Wire diameter: | |

| Availability: | |

| Quantity: | |

MRHWJ

Meirun

8463300000

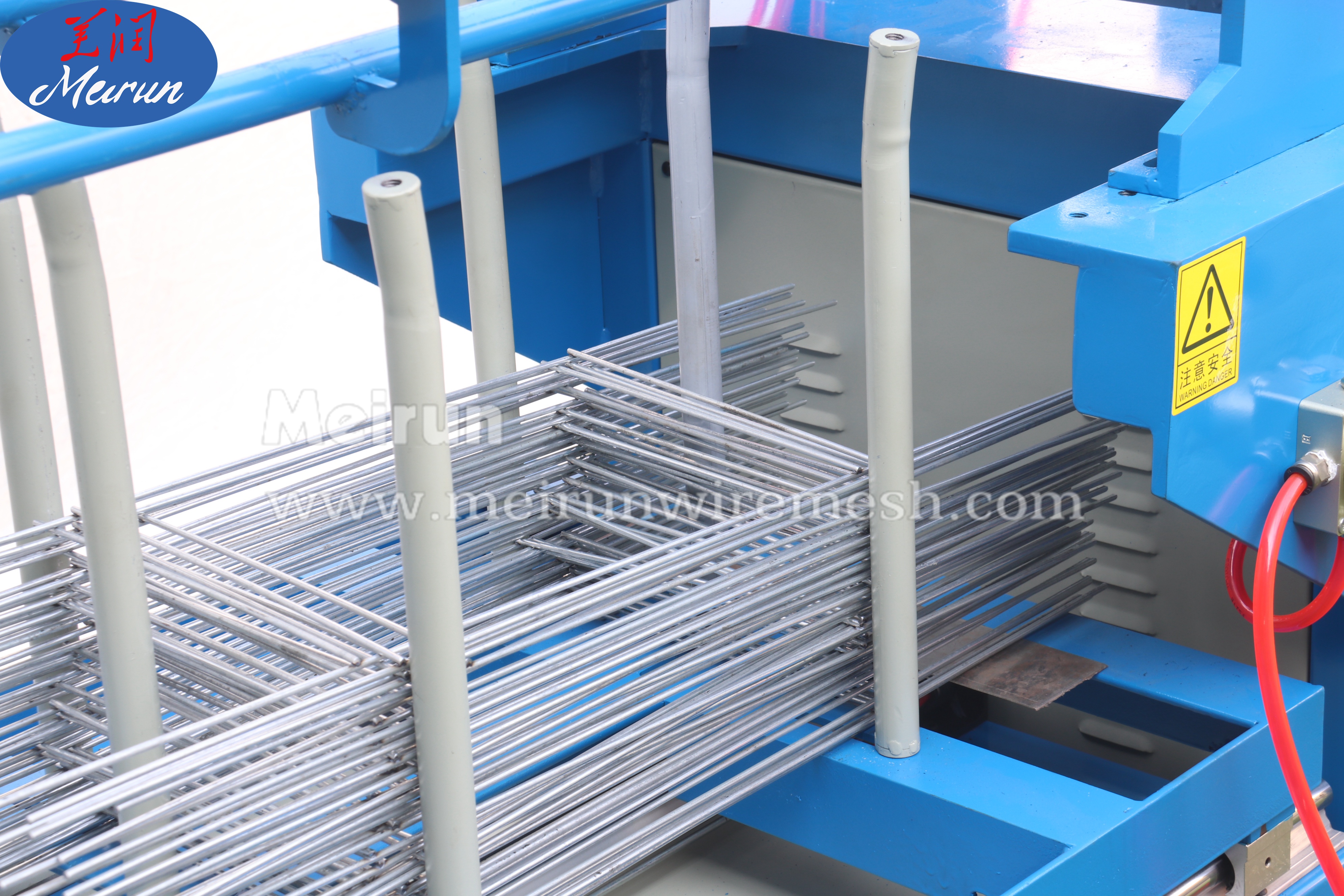

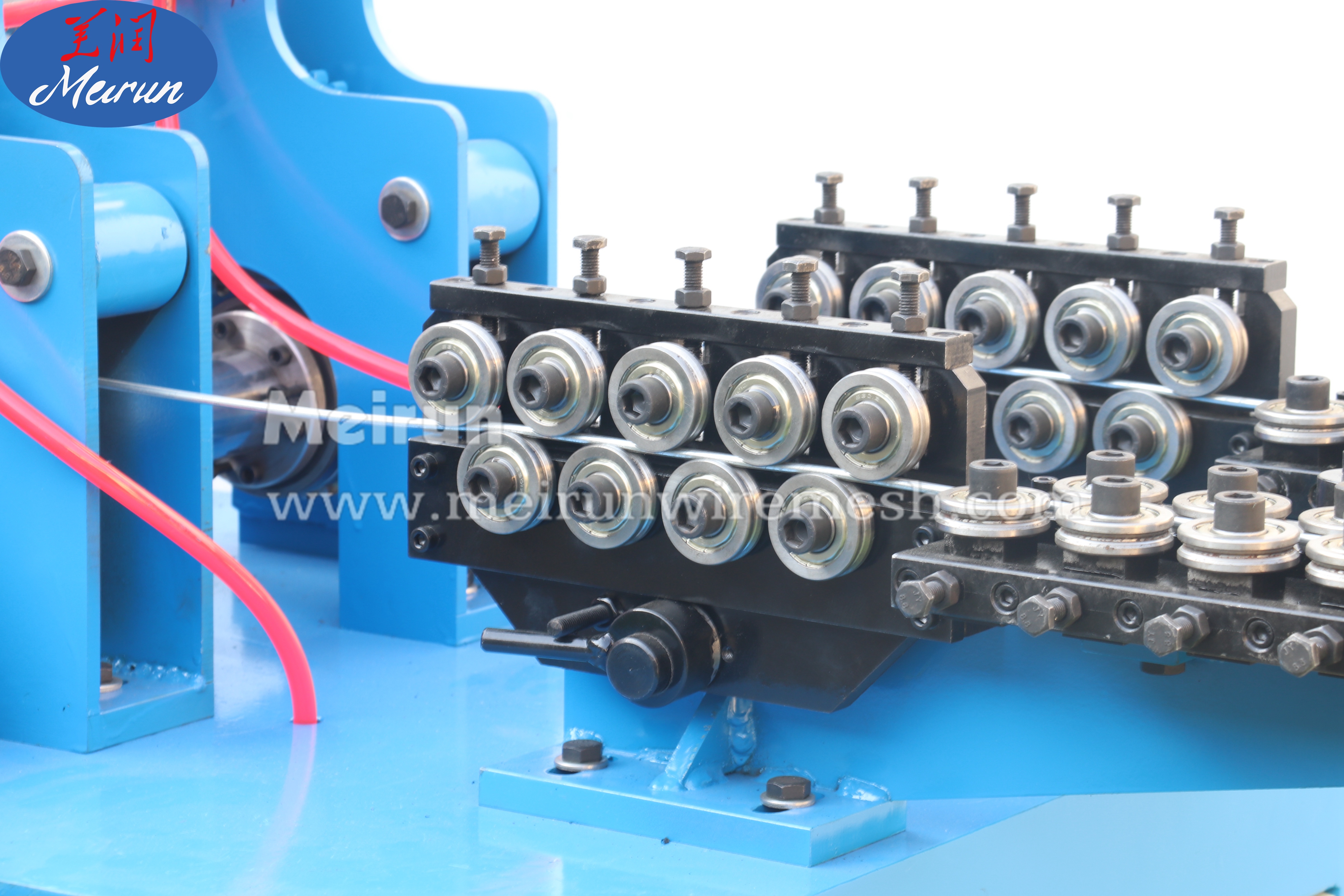

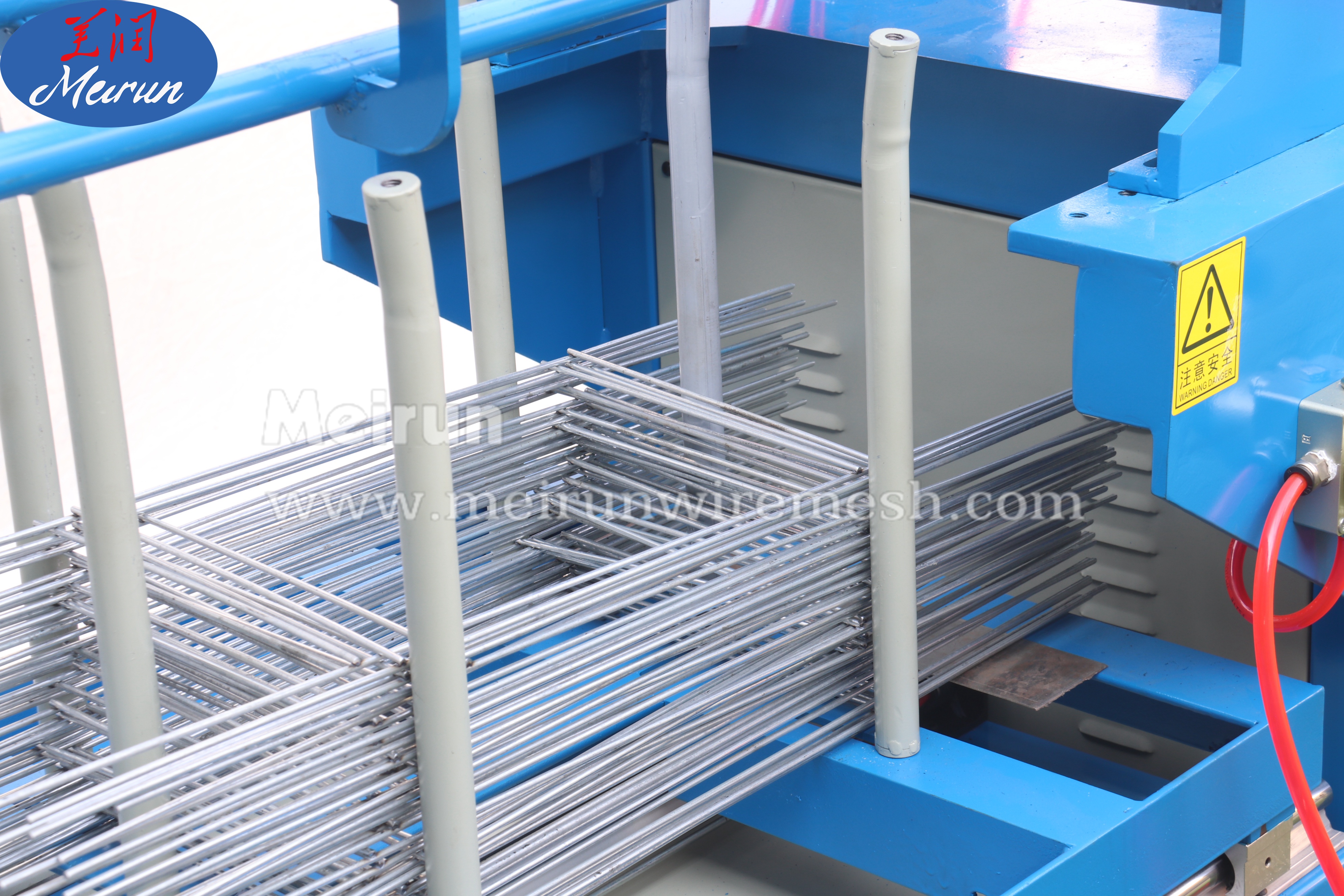

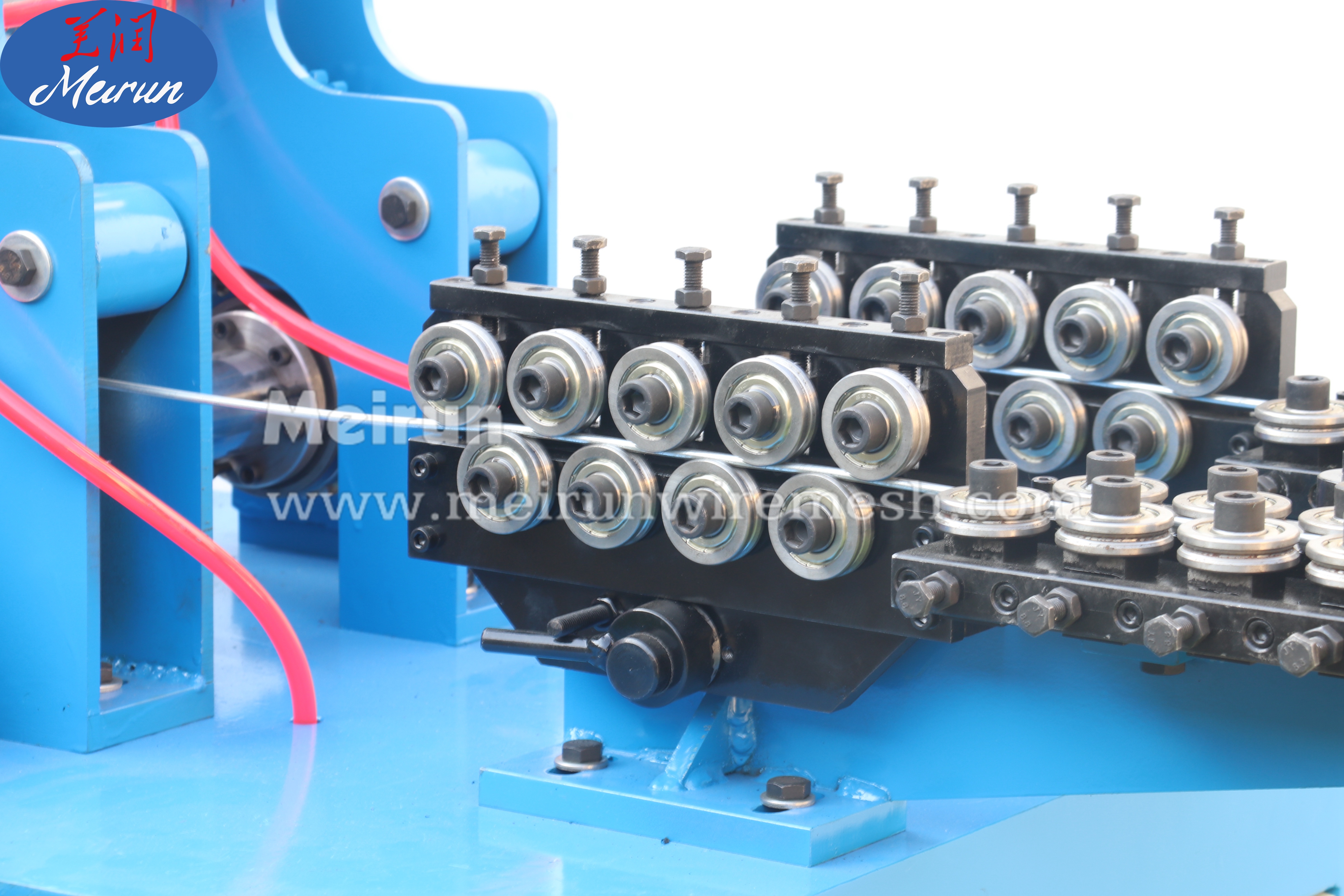

South Africa automatic brick force wire mesh welding machine

The machine adopts numerical control synchronous control technology. The welding time and the sub-control welding time are all composed of PLC digital programming system. The servo motor pulls the mesh, and the input panel is touch screen or keyboard. The operation is more intelligent and rational. The device has the advantages of stable performance, firm solder joints and precise welding dimensions. The machine adopts power electronic synchronous control technology, which can automatically slice and automatically wind up, with high output, stable performance, firm solder joints and no burn marks.

Usage of finished product:It is mainly used for wall reinforcement and has the characteristics of anti-seismic and anti-cracking.

| Model | MR1000 | No. Of electrodes | 6pcs |

| Wire diameter | 1.5-3.0mm | Welding power | 75KVA*1 (water cooling) |

| Main motor | 3.0KW | Cross wire feeding | Coil auto feeding |

| Mesh size | 75-300mm | Line wire feeding | Coil auto feeding |

| Mesh Width | Max1000mm | Weight | 2.5T |

| Welding speed | 50-70/min | Factory transformer required | 100KVA |

| Machine size | 6500*2100*1500mm | ||

| Way of mesh pulling | Controlled by Double servo motor | Way of welding | Control silicon Welding Seperately |

South Africa automatic brick force wire mesh welding machine

The machine adopts numerical control synchronous control technology. The welding time and the sub-control welding time are all composed of PLC digital programming system. The servo motor pulls the mesh, and the input panel is touch screen or keyboard. The operation is more intelligent and rational. The device has the advantages of stable performance, firm solder joints and precise welding dimensions. The machine adopts power electronic synchronous control technology, which can automatically slice and automatically wind up, with high output, stable performance, firm solder joints and no burn marks.

Usage of finished product:It is mainly used for wall reinforcement and has the characteristics of anti-seismic and anti-cracking.

| Model | MR1000 | No. Of electrodes | 6pcs |

| Wire diameter | 1.5-3.0mm | Welding power | 75KVA*1 (water cooling) |

| Main motor | 3.0KW | Cross wire feeding | Coil auto feeding |

| Mesh size | 75-300mm | Line wire feeding | Coil auto feeding |

| Mesh Width | Max1000mm | Weight | 2.5T |

| Welding speed | 50-70/min | Factory transformer required | 100KVA |

| Machine size | 6500*2100*1500mm | ||

| Way of mesh pulling | Controlled by Double servo motor | Way of welding | Control silicon Welding Seperately |