| Availability: | |

|---|---|

| Quantity: | |

MR12

MR

12

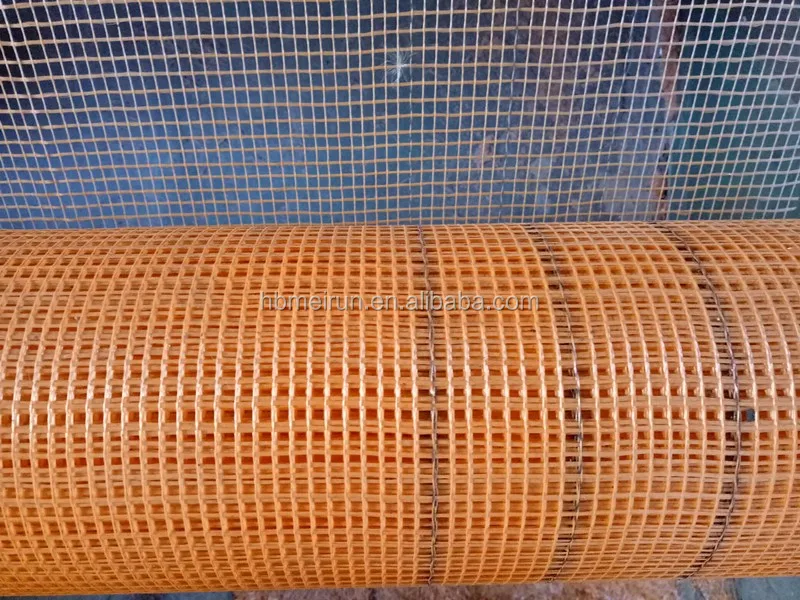

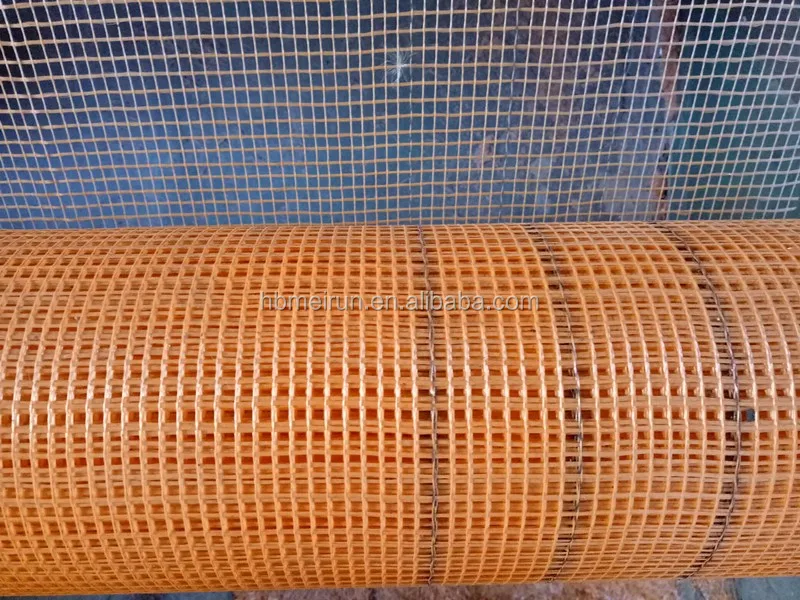

The fiberglass weaving machine is a kind of machinary processing materials such as glass fiber, woven mesh cloth, glass fiber shield, wall mesh and mosaic back mount glass fiber mesh. It can produce various width products,such as 1m,1.2m,1.5m,2.0m,2.3m,2.4m.The density of the mesh cloth can be adjusted from 4 eyes to 12 eyes.

The main raw material is high quality fiberglass wire, it adopts the coated technicians of PVC resin single wire, then through the weaving, shaped-deciding, examine.

| Mesh Size | 4x4mm, 5x5mm,6x6mm |

| Width : | 2000mm ( 2 rollers , every 1000mm ) |

| Length | 50m,100m, and any length required |

| Speed : | 90-140 times/min |

| Production Capacity | 800-1200m/h |

| Motor power | 1.5KW |

| Overall dimension | 4.2x1.8x1.4m |

| Weight | 1.8 tons |

one productino line

1.16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9 mesh, 8x8 mesh, 6x6 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh and so on

2. Weight per sq.meter: 40g to 800g

3. Each roll length: 10m,20m,30m,50m to 300m

4. Width: 1m to 2.2m (61cm 71cm 80cm 100cm 110cm 122cm 142cm 152cm 162cm 183cm)

5. Color: White (standard) blue, green, orange, yellow,black, gray, off-white etc.

6. We can produce many specifications and use different packaging according to customers' requests.

The main usage:

Insect preventing, pasture, orchard, vegetable garden, traffic, industry, healthy, civil, architecture.

1.The spare parts and control cabinet will be loaded in wooden box.

2.The main machine is nude packing or plastic packing.

3.Also can do as customer's request.

Our company:

Our company is a professional screen machinery manufacturing company with many years of experience in China. Our company focuses on the manufacturing and trading of various screen products and related machines.We have our own factory and professional r&d team to ensure the quality and strict testing of the products.For some machines, our market share is as high as 70%.All of our machines are in line with international quality standards and customers' needs and have been greatly appreciated in various markets around the world.So we are your wise choice and best friend.

Our service:

1.If the buyer need,we can send our technical staff to the buyers factory to install the machine and providing the training in 30 days after the machines arrived the destination pory

2.Maintenance period:One year for whole machine except vulnerable parts

3.The number of technical persons :one technician per machine

4.The fees:the buyer have to pay the technical salary 100 USD per day,and the round-trip tiket,accommodation and other related fees

5.During the maintenance period.if the parts are broken caused by the product problem.seller will offer the parts for free,if you need we assign the tachicians to your factory ,then you will pay some related fees.

The fiberglass weaving machine is a kind of machinary processing materials such as glass fiber, woven mesh cloth, glass fiber shield, wall mesh and mosaic back mount glass fiber mesh. It can produce various width products,such as 1m,1.2m,1.5m,2.0m,2.3m,2.4m.The density of the mesh cloth can be adjusted from 4 eyes to 12 eyes.

The main raw material is high quality fiberglass wire, it adopts the coated technicians of PVC resin single wire, then through the weaving, shaped-deciding, examine.

| Mesh Size | 4x4mm, 5x5mm,6x6mm |

| Width : | 2000mm ( 2 rollers , every 1000mm ) |

| Length | 50m,100m, and any length required |

| Speed : | 90-140 times/min |

| Production Capacity | 800-1200m/h |

| Motor power | 1.5KW |

| Overall dimension | 4.2x1.8x1.4m |

| Weight | 1.8 tons |

one productino line

1.16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9 mesh, 8x8 mesh, 6x6 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh and so on

2. Weight per sq.meter: 40g to 800g

3. Each roll length: 10m,20m,30m,50m to 300m

4. Width: 1m to 2.2m (61cm 71cm 80cm 100cm 110cm 122cm 142cm 152cm 162cm 183cm)

5. Color: White (standard) blue, green, orange, yellow,black, gray, off-white etc.

6. We can produce many specifications and use different packaging according to customers' requests.

The main usage:

Insect preventing, pasture, orchard, vegetable garden, traffic, industry, healthy, civil, architecture.

1.The spare parts and control cabinet will be loaded in wooden box.

2.The main machine is nude packing or plastic packing.

3.Also can do as customer's request.

Our company:

Our company is a professional screen machinery manufacturing company with many years of experience in China. Our company focuses on the manufacturing and trading of various screen products and related machines.We have our own factory and professional r&d team to ensure the quality and strict testing of the products.For some machines, our market share is as high as 70%.All of our machines are in line with international quality standards and customers' needs and have been greatly appreciated in various markets around the world.So we are your wise choice and best friend.

Our service:

1.If the buyer need,we can send our technical staff to the buyers factory to install the machine and providing the training in 30 days after the machines arrived the destination pory

2.Maintenance period:One year for whole machine except vulnerable parts

3.The number of technical persons :one technician per machine

4.The fees:the buyer have to pay the technical salary 100 USD per day,and the round-trip tiket,accommodation and other related fees

5.During the maintenance period.if the parts are broken caused by the product problem.seller will offer the parts for free,if you need we assign the tachicians to your factory ,then you will pay some related fees.